Jannik

Suitable for any occasion

Ucon Acrobatics

Jannik Mini Backpack

Lotus Infinity Series

Timeless elegance in vibrant colors

Ucon Acrobatics

Lotus Infinity Series

MINIMAL DESIGN

Our durable, timeless designs for urban nomads are the result of environmentally friendly and social decisions as well as passion and creativity.

MINIMAL EMISSION

We want to create the best product possible without causing any unnecessary damage. For this plan to work and for us to be able to inspire and implement environmental solutions, we work with carefully selected associations and partners.

A Change in Material - A Change for the Climate

Here are the key innovations

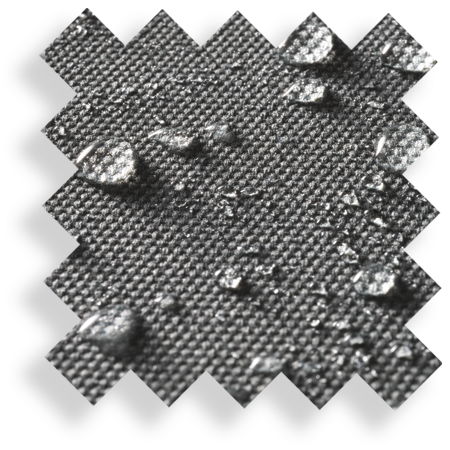

Largest possible percentage of recycled textiles

Extended lifetime

Reduced ecological footprint

Designed for the circular economy

How would such a 'innovation' look like?

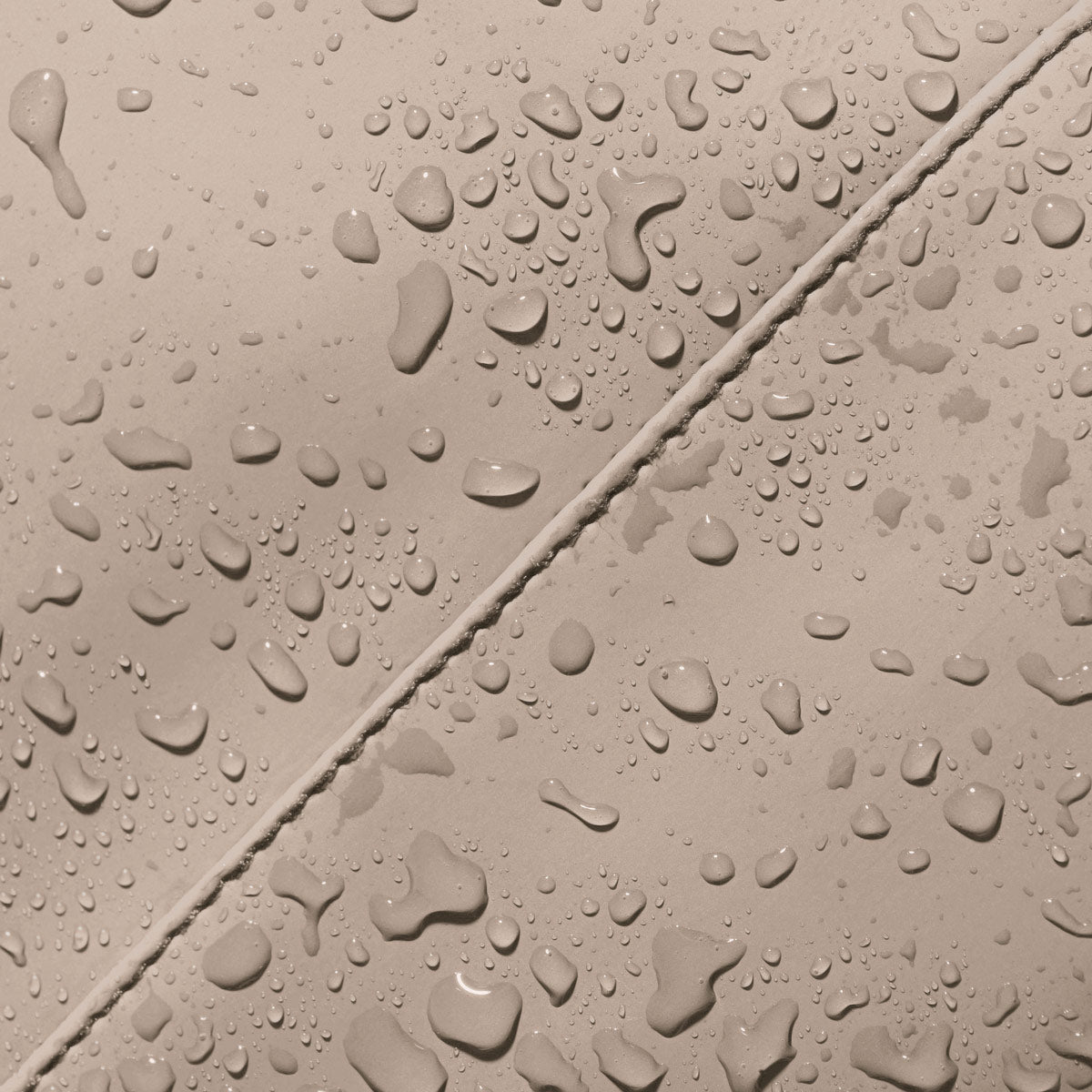

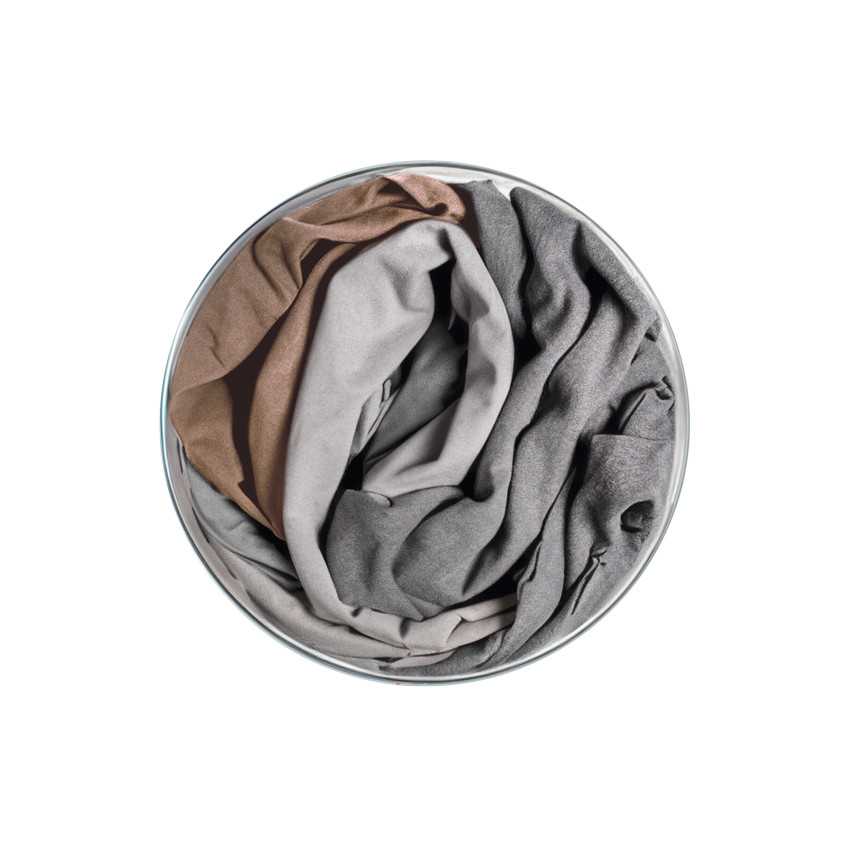

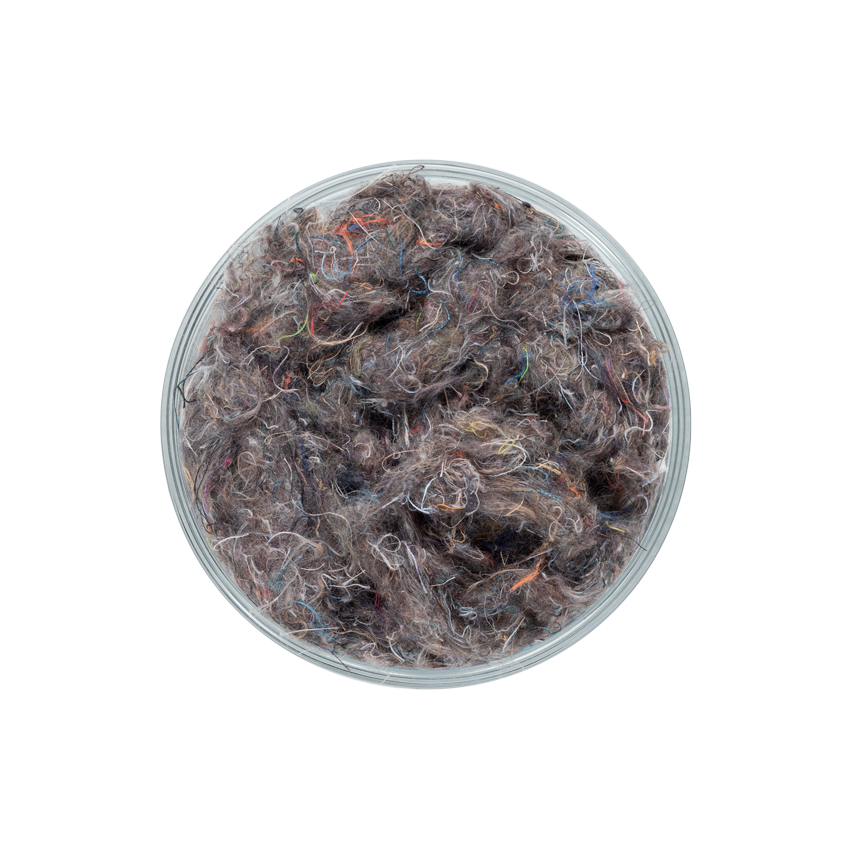

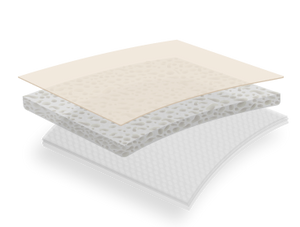

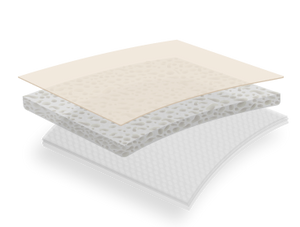

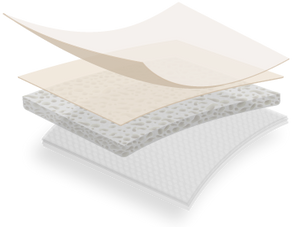

Sustainability doesn't always have to look 'eco'. In our case, you can hardly tell the difference. Often they are not visible, because we look where no one looks. Hard plastics and foams are hidden in every backpack sold today. We have found a way to avoid all of that and use textile waste instead.

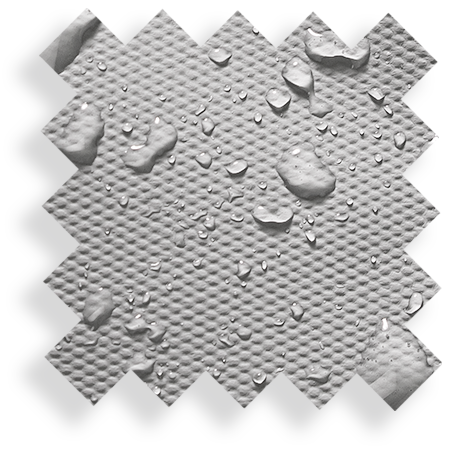

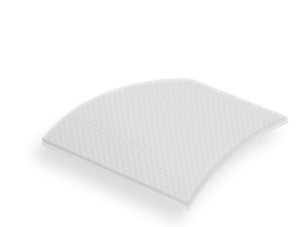

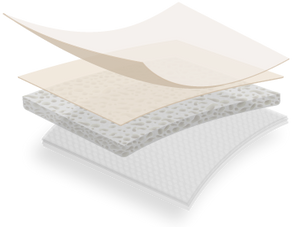

Lotus Infinity Material 'PUrTEX∞'

Tensile strength

Tear resistance

Adhesion resistance

Abrasion resistance

Ecologi

Together with our gold standard partner Ecologi we planted 25.000 trees in 2022 mainly through the 'Eden Reforestation Project'. With each purchased product in our online shop our customers help to plant one more tree and let our forest grow.